UK TRPR Regulations At A Glance:

Visit The UK Gov Website To Learn More-

Vape tanks, pods or any cartridges containing e-liquid cannot exceed 2ml in capacity.

-

E-liquid bottles cannot be sold in volumes over 10ml if the e-liquid contains nicotine.

-

E-liquids cannot contain additives or dangerous ingredients such as known carcinogens, caffeine, taurine, or Diacetyl (the compound linked to popcorn lung).

-

E-liquids cannot be produced with a nicotine content above 20mg/ml.

-

All vape product packaging must feature tamper-evident and childproof mechanisms.

-

All vape packaging must clearly show al relevant warning pictograms and hazard statements, with fully disclosed ingredient and allergen information.

-

All vaping products must be submitted to a range of toxicology and emisisons tests to ensure no dangerous components are produced beyind safe thresholds when vaped. This data must then be submitted to the Medicines and Healthcare product Regulatory Agency (MHRA) for approval and registration before the product can be legally sold.

Raw Material Testing

Every single raw material that is used in making our e-liquids such as VG, PG, flavourings and nicotine are individually tested prior to being added to the e-liquid recipe and these checks are recorded and each component is fully traceable should any issues arise.

Pharmaceutical & Food-Grade Ingredients

We only ever use pharmaceutical & food-grade raw materials when making our e-liquids. This includes the Vegetable Glycerol (VG) and Propylene Glycol (PG) used as the base for finished batches but also as carrier agents for our flavour and nicotine dilutions. All of our flavourings and nicotine dilutions are produced in-house by our expert UK lab teams.

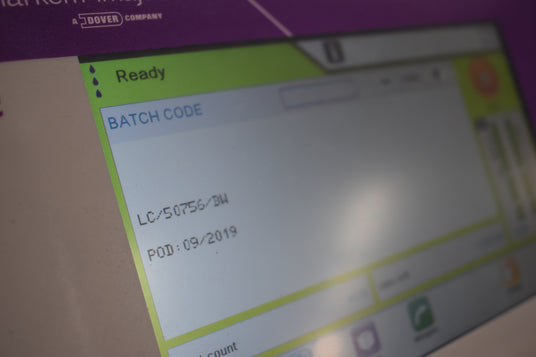

Batch-Testing & Batch Codes On Every bottle

Once an e-liquid batch has been produced, it is assigned a code and subjected to a wide range of analytical tests by our QC and lab teams, to ensure it meets not only legal requirements but also our own safety and quality standards. These batch codes are then sprayed onto the base of every single bottle that the batch is decanted into. This creates total traceability for every component that went into the batch.

If you should experience an issue of any kind, you can provide our customer care team with the batch code, allowing us to conduct a strict internal quality and safety assessment to resolve any issues and provide EDGE customers with peace of mind.